First, the battery shall be from international well known brands and has UL certificate. The supplier shall have at least 5 years of experience in serving North American major brand customers. The supplier shall provide business license, self-evaluation form (including production and supply capacity), regulatory agreement, test report, qualification document, product certificate, etc., and then present the samples for Phenix’s evaluation.

For the test confirmation of battery samples, Phenix Lighting has its own testing requirements and methods.

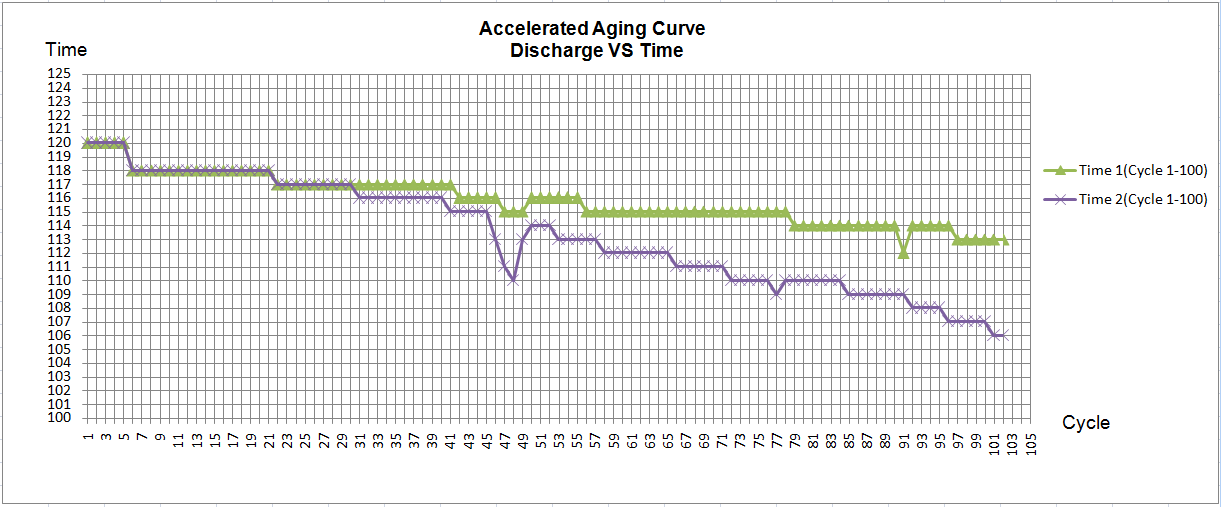

Besides the measurable parameters confirmation as per product specifications/test report that both sides confirm in advance, e.g.: battery’s voltage, capacity, size, charging and discharging time and watts at low, normal and high temperatures etc., the battery sample needs to be conducted 100 cycles of accelerated aging (charge and discharge) test for 20 working days. This method provides good evidence of the battery supplier’s quality and potential long-term reliability. And using this method, we performed the same tests at 0 ° C and 50 ° C, and the degradation curve at 50 ° C is a better indicator of battery life degradation.

The following is an example of Phenix Lighting 100 cycles of accelerated aging test for a Li-ion battery pack:

Prior to starting the 50℃ high temperature test: Trickle charge the battery till the battery is full charged (24 hours)

- Measure Battery voltage at full charge “T0” as zero minute of discharge.

- Complete discharge (Discharge load shall be based on the highest rated load). Measure and record the discharge voltage and current at least every 5 minutes during the discharge process.

- Fast charge with 1C high current for 55 minutes.

- Repeat Step #1 (100 cycles in total; each cycle need ~3 hours; 5 cycles per day x ~20 days = 100 cycles).

- Compare battery performance between early cycles and late cycles.

The resulting message is an “accelerated aging curve” as shown below:

Notes:

Time 1: Battery sample #1

Time 2: Battery sample #2

Determination criteria: attenuation of each sample < 10%

The attenuation of sample #1 is: (120-113) /120=5.83%, which is less than 10%, so judged qualified.

The attenuation of sample #2 is: (120-106) /120=11.67%, which is more than 10%, so judged unqualified

However, because the sample #2 failed, this battery from this supplier was finally judged unqualified.

This method can test the performance and reliability of the Li-ion batteries in a relatively short period of time. The tests show significant differences between the performance of the top performing brands and other normal brands- even that their initial performances seem almost same.

Finally, Phenix Lighting will keep the annual assessment of the battery suppliers to confirm whether the qualification is maintained or not.

Post time: Nov-25-2022